Unveiling The Artistry: Exploring The World Of Vinyl Roll Manufacturing

Welcome to the captivating universe of vinyl roll manufacturing, where artistry intertwines with technology. In this article, we embark on a thrilling expedition, uncovering the secrets and intricacies behind the creation of vinyl rolls. From the enchanting process of transforming raw materials into vibrant patterns, to the cutting-edge techniques propelling this timeless craft forward, prepare to immerse yourself in a world of superior craftsmanship. Join us on this enlightening journey as we delve into the depths of vinyl roll manufacturing, unravelling the enigma and celebrating the mastery behind this enduring art form.

Understanding the Basics: What is Vinyl Roll Manufacturing?

Understanding the Basics: What is Vinyl Roll Manufacturing?

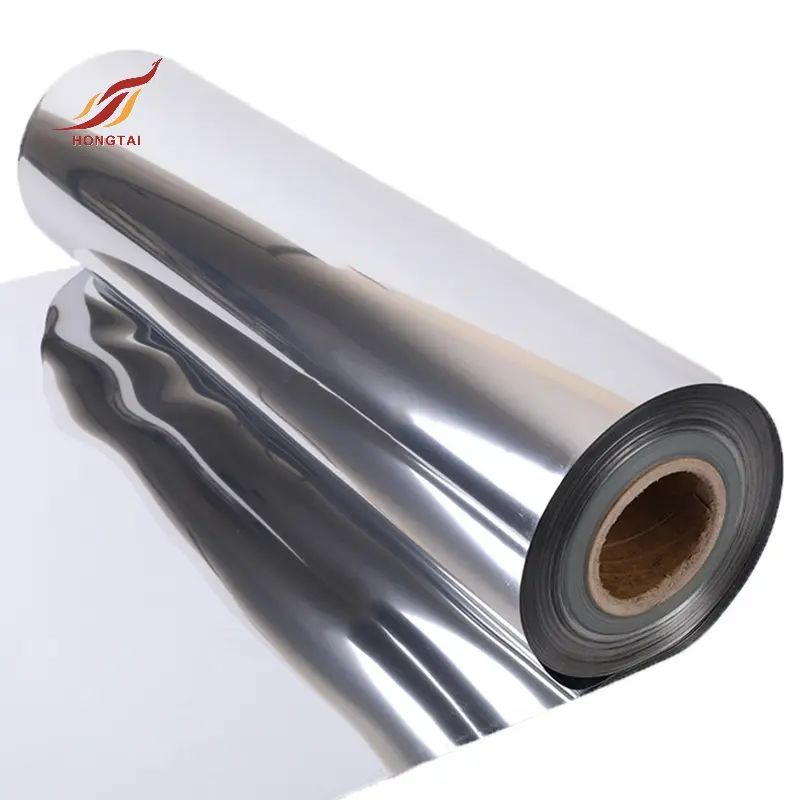

Vinyl roll manufacturing is a process that involves the creation of large rolls of vinyl material, which are widely used in various industries, including signage, advertising, packaging, and transportation. As a leading name in the industry, KunLin specializes in the production of high-quality vinyl rolls that meet the diverse needs of customers worldwide.

Vinyl roll manufacturing begins with the selection of raw materials. Vinyl is a versatile and durable material made from polyvinyl chloride (PVC) resin. This resin is combined with plasticizers, stabilizers, and pigments to create a flexible and functional material that can be used for a wide range of applications. KunLin ensures that only the finest quality PVC resin is used in the production process to guarantee the longevity and reliability of their vinyl rolls.

The next step in the manufacturing process is the calendaring process. Calendaring refers to the process of passing the vinyl material through a series of heated rollers to create a uniform and smooth surface. This process not only enhances the aesthetics but also improves the overall durability and strength of the vinyl rolls. KunLin utilizes state-of-the-art calendaring machines, along with advanced temperature and pressure control technology, to ensure the highest level of precision and consistency in their manufacturing process.

Once the calendaring process is complete, the vinyl material is ready for customization. KunLin offers a wide range of customization options to meet the unique requirements of different industries and applications. This includes the ability to choose from various thicknesses, widths, colors, and finishes. Whether it's for outdoor signage, vehicle wrapping, or product packaging, KunLin can provide vinyl rolls that are tailored to specific needs, ensuring optimal performance and visual appeal.

Quality control is of utmost importance in vinyl roll manufacturing. KunLin employs a rigorous quality management system that encompasses every stage of the production process. Thorough inspections are conducted to ensure that the vinyl rolls meet industry standards for durability, flexibility, color fastness, and resistance to UV rays and weather conditions. KunLin prioritizes customer satisfaction, and their commitment to delivering consistently high-quality products has earned them a reputation as a reliable and trusted vinyl roll manufacturer.

In addition to their focus on quality, KunLin is also dedicated to environmental sustainability. They recognize the importance of minimizing their carbon footprint and have implemented eco-friendly practices throughout their manufacturing process. This includes the use of non-toxic materials, the implementation of energy-efficient machinery, and the responsible disposal and recycling of waste materials. By choosing KunLin as a vinyl roll manufacturer, customers can be confident that they are contributing to a greener and more sustainable future.

In conclusion, vinyl roll manufacturing plays a crucial role in various industries, providing durable and versatile materials for a wide range of applications. KunLin, as a leading vinyl roll manufacturer, utilizes top-quality raw materials, advanced production techniques, and a commitment to quality and sustainability to deliver exceptional products to their customers. Whether it's for signage, advertising, packaging, or transportation, KunLin's vinyl rolls are designed to meet and exceed industry standards, making them the preferred choice for businesses worldwide.

The Intricate Process: How Vinyl Rolls are Crafted

Unveiling the Artistry: Exploring the World of Vinyl Roll Manufacturing

Vinyl roll manufacturing is an intricate process that requires precision, skill, and an unwavering commitment to quality. At KunLin, a leading vinyl roll manufacturer, this process is regarded as an art form, where every step is meticulously executed to create a product that is not only visually stunning but also built to last.

The journey begins with the selection of the finest raw materials. KunLin sources high-quality vinyl compounds from trusted suppliers, ensuring that only the best ingredients are used in the manufacturing process. These compounds are then carefully blended with colorants and additives to achieve a vibrant and durable end product.

Once the perfect blend is achieved, the next step is to transform the mixture into a rollable form. The compound is fed into an extruder, which operates at high temperatures to melt the vinyl and create a homogeneous mass. This molten vinyl is then passed through a series of rollers, which shape it into a continuous sheet and eliminate any air bubbles or impurities.

The sheet is then cooled rapidly to set its shape and ensure uniformity. This rapid cooling process, known as quenching, is crucial to prevent warping and distortions in the final product. KunLin utilizes advanced cooling techniques to achieve optimal results and maintain the highest level of product integrity.

Once the sheet has been cooled, it is inspected rigorously to ensure that it meets KunLin's strict quality standards. Skilled technicians meticulously examine the sheet for any imperfections, such as surface irregularities or color inconsistencies, and reject any subpar materials. Only the sheets that pass this meticulous inspection are deemed suitable for further processing.

The accepted sheets are then sent to the cutting department, where they are trimmed to the desired width and length. KunLin employs state-of-the-art cutting machines that guarantee precision and efficiency, ensuring that every roll is uniform in size and shape. This attention to detail is what sets KunLin apart from other manufacturers, as the company's commitment to excellence shines through in every aspect of the manufacturing process.

Once the sheets have been cut, they are ready to be transformed into vinyl rolls. KunLin's skilled craftsmen operate specialized rolling machines, which carefully wind the sheets into tight rolls with utmost precision. This step requires great skill and concentration, as any errors can result in uneven or loose rolls. The craftsmen take pride in their work, ensuring that every roll is flawlessly crafted.

Finally, the rolls undergo a final inspection before they leave the manufacturing facility. KunLin's quality control team examines each roll for any remaining imperfections and confirms that it meets the company's strict standards. Once the rolls receive the stamp of approval, they are ready to be shipped to customers worldwide, bringing the artistry of vinyl roll manufacturing to homes and businesses around the globe.

In conclusion, vinyl roll manufacturing is a meticulous and intricate process that requires skill, precision, and an unwavering commitment to quality. From the careful selection of raw materials to the precise cutting and rolling techniques, every step in the process is crucial to producing vinyl rolls that are visually stunning and built to last. At KunLin, this artistry is celebrated, ensuring that customers receive a product that exceeds their expectations and adds beauty to their spaces. So next time you unroll a vinyl floor or wallpaper, take a moment to appreciate the craftsmanship and dedication that went into creating it.

Choosing Quality Materials: Exploring Raw Materials Used in Manufacturing

Choosing Quality Materials: Exploring Raw Materials Used in Manufacturing

Vinyl roll manufacturing is a complex and meticulous process that involves various stages, from selecting the right raw materials to delivering a high-quality end product. In this article, we delve into the world of vinyl roll manufacturing, shedding light on the artistry and craftsmanship involved, with a particular focus on the importance of choosing quality materials.

As a leading vinyl roll manufacturer, KunLin understands the significance of starting with superior raw materials. A vinyl roll, also known as a PVC film or sheet, is primarily made from polyvinyl chloride (PVC) and other additives, which enhance its physical and aesthetic properties. However, not all PVC materials are created equal, and KunLin takes great care in sourcing from reputable suppliers.

One key factor in choosing quality materials for vinyl roll production is the PVC resin itself. PVC resin is the primary building block of PVC products and is available in different grades. Higher-grade PVC resin offers better durability, flexibility, and resistance to chemicals and UV rays, ensuring that the vinyl rolls produced maintain their integrity and aesthetic appeal, even under harsh conditions.

In addition to selecting the appropriate PVC resin, KunLin pays close attention to the additives used in the production process. These additives bring specific properties to the vinyl rolls, such as flame retardancy, thermal stability, or anti-static capabilities. By carefully selecting additives from trusted suppliers, KunLin ensures that its vinyl rolls meet the desired performance standards and fulfill the requirements of various industries and applications.

Another crucial aspect of manufacturing vinyl rolls is the reinforcement materials used. These materials, such as polyester or nylon, are embedded within the PVC film to provide additional strength and dimensional stability. KunLin recognizes the importance of using high-quality reinforcement materials to enhance the overall performance and longevity of its vinyl rolls.

Furthermore, the process of manufacturing vinyl rolls involves various techniques, such as calendaring or extrusion. Calendaring involves passing the mixture of PVC and additives through heavy rollers, creating a thin and uniform film. This technique requires precision and control to ensure consistent thickness and smoothness across the entire vinyl roll. Similarly, extrusion involves forcing the PVC material through a die, resulting in a continuous sheet of the desired width and thickness. These manufacturing techniques demand not only skill and expertise but also the use of top-quality materials to achieve desired outcomes.

KunLin's commitment to using quality materials extends beyond the production stage. The company also pays attention to the sourcing and handling of its raw materials. By partnering with responsible suppliers who comply with industry standards and regulations, KunLin ensures the sustainability and ethicality of its supply chain.

In conclusion, vinyl roll manufacturing is a craft that requires careful consideration of the materials used. KunLin, as a leading vinyl roll manufacturer, understands the importance of choosing quality materials from reputable suppliers. From selecting the right PVC resin to employing top-notch additives and reinforcement materials, KunLin's commitment to quality shines through each step of the manufacturing process. By prioritizing the use of premium materials, KunLin ensures that its vinyl rolls deliver exceptional performance, durability, and aesthetic appeal for various applications.

Unleashing Creativity: Customization and Design Possibilities in Vinyl Roll Manufacturing

Unveiling the Artistry: Exploring the World of Vinyl Roll Manufacturing

Subtitle: Unleashing Creativity: Customization and Design Possibilities in Vinyl Roll Manufacturing

Vinyl Roll manufacturing has come a long way since its inception, with the advancement in technology pushing the boundaries of creativity and design possibilities. At KunLin, a leading vinyl roll manufacturer, the artistry behind vinyl roll production has been unraveled, captivating industries and individuals alike.

With an ever-increasing demand for unique and personalized products, customization has become a crucial aspect of vinyl roll manufacturing. KunLin understands the need for individuality and offers a wide range of customization options, enabling customers to create one-of-a-kind designs that truly reflect their style and vision.

One of the key advantages of vinyl roll manufacturing at KunLin lies in their cutting-edge technology. Utilizing state-of-the-art printing techniques, they can replicate intricate patterns and designs with precision and accuracy. Whether it's replicating a vintage textile pattern or creating a custom graphic design, KunLin's technology ensures that every detail is brought to life on the vinyl roll.

In addition to customization, KunLin also offers a vast selection of design possibilities. Their extensive library of patterns, colors, and textures provides customers with endless options to choose from. From classic and elegant designs to bold and contemporary styles, there is something to suit every taste and preference.

Moreover, KunLin recognizes the importance of sustainability in the manufacturing process. They are committed to using eco-friendly materials that are free from harmful chemicals, making their vinyl rolls not only visually appealing but also safe for both the environment and consumers.

Vinyl rolls have found their applications in various industries, ranging from fashion and interior design to automotive and advertising. In the fashion industry, vinyl rolls have revolutionized the creation of unique garments and accessories. Designers can now experiment with different textures, colors, and patterns, resulting in extraordinary pieces that capture attention and push boundaries.

Vinyl roll customization has also paved the way for personalized home decor. By selecting from KunLin's vast range of designs, homeowners can transform their living spaces into unique havens, reflecting their individual taste and style. From walls to floors, vinyl rolls offer a versatile and cost-effective solution for creating stunning interiors.

The automotive industry has also embraced the artistry of vinyl roll manufacturing. Custom car wraps have become increasingly popular, allowing car enthusiasts to personalize their vehicles and make a bold statement on the roads. With the ability to replicate intricate designs, vinyl rolls offer endless possibilities for creating striking and eye-catching car wraps.

Vinyl roll advertising has also witnessed a transformation. With the use of custom-printed vinyl rolls, businesses can now create visually captivating advertisements that leave a lasting impression on viewers. From banners and billboards to vehicle wraps, vinyl roll applications in advertising are only limited by imagination.

In conclusion, the world of vinyl roll manufacturing is a vibrant and dynamic one, driven by the desire for customization and design possibilities. KunLin, with its commitment to pushing boundaries and embracing innovation, offers a platform for individuals and industries to unleash their creativity. With personalized options, cutting-edge technology, and a wide range of designs, vinyl rolls have become the go-to choice for those seeking to add a touch of artistry to their projects.

Market Insights: Applications and Industries Benefiting from Vinyl Roll Manufacturing

Unveiling the Artistry: Exploring the World of Vinyl Roll Manufacturing

Market Insights: Applications and Industries Benefiting from Vinyl Roll Manufacturing

Vinyl roll manufacturing has emerged as a dynamic and innovative industry, presenting an array of opportunities for applications and numerous industries. As the keyword "vinyl roll manufacturer" gains traction in the market, one name that stands out is KunLin— a leading player revolutionizing the field with its expertise and commitment to quality.

Vinyl rolls, a flexible and versatile material, have found their way into a diverse range of applications. From interior design to automotive manufacturing, the demand for vinyl rolls has been steadily increasing. KunLin, a renowned vinyl roll manufacturer, has recognized this potential and captured it by exceeding customer expectations with its exceptional products.

One of the primary sectors benefiting from vinyl roll manufacturing is interior design. Offering a plethora of colors, textures, and patterns, vinyl rolls have become a popular choice for creating stunning wall coverings, floorings, and furniture upholstery. Their durability, ease of maintenance, and cost-effectiveness make them the go-to choice for designers seeking to transform spaces with a touch of elegance and practicality.

Furthermore, the automotive industry has also witnessed a surge in the use of vinyl rolls for various purposes. From vehicle interiors to exterior graphics, vinyl rolls have become a preferred medium for customization and branding. Being highly resistant to moisture, UV radiation, and harsh weather conditions, vinyl rolls ensure long-lasting vibrancy and protection. KunLin, as a leading vinyl roll manufacturer, has mastered the art of producing top-quality rolls that meet the rigorous requirements of the automotive industry.

In addition to interior design and automotive sectors, vinyl roll manufacturing has found extensive applications in advertising and signage. Vinyl rolls serve as the perfect medium for eye-catching banners, billboards, and wraps. Its versatility allows vivid and high-resolution graphics to be printed, enhancing brand visibility and attracting potential customers. KunLin understands the significance of quality in this field, and their vinyl rolls provide exceptional printability, durability, and color retention.

Another arena that has hugely benefited from vinyl roll manufacturing is the packaging industry. The ability of vinyl rolls to offer secure and attractive packaging solutions has made them an essential choice for various products, ranging from food items to electronics. Not only do vinyl rolls provide protection from moisture, dust, and other external factors, but they also act as an excellent branding tool. KunLin's vinyl rolls, known for their reliability and consistent performance, have made a significant impact in the packaging industry.

Moreover, the healthcare and pharmaceutical sectors have also witnessed the advantages of vinyl rolls. These rolls are extensively used for medical equipment wraps, protective coverings for sensitive machinery, and pharmaceutical packaging. Their antibacterial properties and resistance to chemicals make them an ideal choice in environments that require stringent hygiene standards.

The potential for applications in vinyl roll manufacturing is boundless, and KunLin, as a leading player in the industry, continues to explore new possibilities. By investing in research and development, KunLin ensures that their vinyl rolls are at the forefront of technological advancements. Their commitment to sustainability and eco-friendly practices further solidifies their position as a go-to vinyl roll manufacturer.

In conclusion, the world of vinyl roll manufacturing offers a diverse range of applications and industries that benefit immensely from its versatility and quality. With KunLin leading the way, this industry continues to evolve and provide innovative solutions for interior design, automotive, advertising, packaging, healthcare, and pharmaceutical sectors. As the market expands, the keyword "vinyl roll manufacturer" will continue to garner attention, with KunLin at the forefront of this flourishing industry.

Conclusion

1. The Importance of Vinyl Roll Manufacturing in Heritage Preservation:

Throughout this article, we have delved into the intricate world of vinyl roll manufacturing and its incredible contributions to heritage preservation. By combining technical expertise with artistic creativity, manufacturers have managed to revive and reproduce countless iconic designs from the past. Not only does this keep the spirit of these artworks alive, but it also offers a tangible connection to our cultural heritage for future generations. As we wrap up our exploration into this fascinating industry, it is clear that vinyl roll manufacturing serves as an invaluable gateway to preserving our artistic legacy.

2. The Innovative Techniques Revolutionizing Vinyl Roll Manufacturing:

From the traditional craftsman techniques to cutting-edge digital printing technologies, vinyl roll manufacturing has undoubtedly undergone a significant transformation. As we conclude this article, it becomes evident that innovation is at the core of this thriving industry. With advancements such as embossing, letterpress printing, and UV coating, manufacturers are constantly pushing the boundaries to produce vinyl rolls that capture every detail and texture with astonishing accuracy. The future of vinyl roll manufacturing promises even more groundbreaking techniques, ensuring that art enthusiasts will continue to be captivated by the high-quality and captivating productions.

3. Sustainability: The Next Chapter in Vinyl Roll Manufacturing:

In the quest for a greener future, sustainability has emerged as a crucial aspect within the vinyl roll manufacturing industry. As highlighted throughout this article, manufacturers are taking proactive steps to minimize their ecological impact by using eco-friendly materials, implementing energy-efficient production processes, and encouraging recycling. These efforts not only benefit the environment but also demonstrate the industry's commitment to responsible manufacturing practices. As we come to the end of our exploration into the world of vinyl roll manufacturing, it is inspiring to witness the growing prominence of sustainability and the role it plays in shaping the future of this enriching art form.

In conclusion, this article has provided a comprehensive glimpse into the realm of vinyl roll manufacturing, emphasizing its significance in heritage preservation, its continuous pursuit of innovation, and its commitment to sustainability. As we reflect on the artists, craftsmen, and manufacturers who bring these vinyl rolls to life, it is undeniable that their dedication ensures the preservation and appreciation of art for generations to come. So, next time you catch a glimpse of a vinyl roll, take a moment to truly admire the artistry behind its creation, as it represents the cumulative efforts of an industry that celebrates the past, embraces the present, and looks forward to a vibrant and sustainable future.